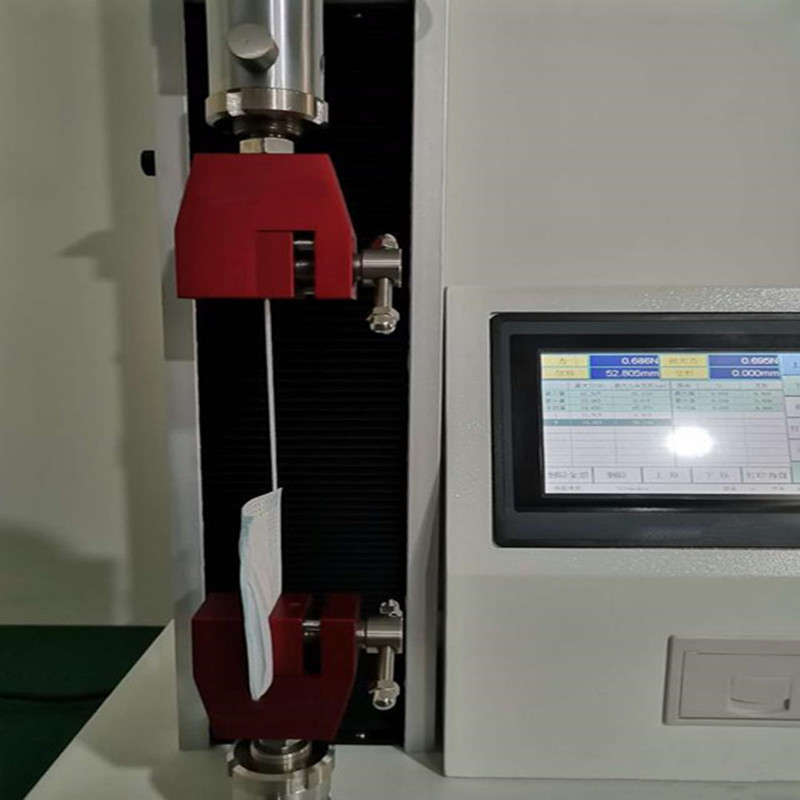

Mask tensile testing machine tests the static tensile force and breaking strengt

The mask tensile testing machine can complete the static tensile test and breaking strength test of ear-hook mask straps, and different modes are used during the test. The static tensile test applies a constant tensile force to the sample and keeps it for a certain period to see if the connection between the mask strap and the mask body is broken. The breaking strength test is to place the sample between the upper and lower clamps, stretch the mask strap and the mask body at a test speed of 100mm/min until the breaking position, and measure the breaking force, expressed in N.

I. Static tensile test of mask straps:

Test materials:

10 medical masks

1. Sample preparation: Randomly select 4 masks, 2 of which are pretreated with temperature and humidity, and 2 are not pretreated.

2. Temperature and humidity pretreatment: According to GB/T19083-2010 Technical Requirements for Medical Protective Masks 5.3.2 Temperature pretreatment conditions.

Pretreatment method: Take out the sample from its original packaging and treat it in the following conditions in sequence:

a) Treat it in an environment of (38±2.5)℃ and (85±5)% relative humidity for (24±1)h;

b) Treat it in a dry environment of (70±3)℃ for (24±1)h;

c) Treat it in a dry environment of (-30±3)℃ for (24±1)h.

The sample temperature should be restored to room temperature for at least 4h before subsequent testing.

3. Determine the test speed:

Adjust the distance between the test hook and the lower clamp, hang the mask strap vertically on the test hook, and clamp the mask body between the lower clamps. Perform a predictive test first to find out the test speed at which the sample breaks within (20±5)s.

4. Parameter setting:

Start the mask tensile tester, select the mask strap static tensile test mode, and set the clamp spacing, test speed, return speed, set force value, and duration test parameters.

5. Place the sample:

Hang the mask strap vertically on the test hook, and clamp the mask body between the lower clamps.

6. Test test:

Start the instrument, start the test, the test ends, and the test results are displayed on the screen.

II. Test test of the breaking force of the mask strap:

Daily protective masks are tested by the constant speed stretching method.

Test materials:

10 daily protective masks

Test process:

1. Sample preparation: Randomly select 5 masks and perform according to GB/T 13773.2.

2. Temperature and humidity treatment: The test temperature is 20℃ and the relative humidity is 65%.

3. Parameter setting: Select the breaking force test mode, and set the test parameters such as the chuck spacing, test speed (100mm/min), and return speed.

4. Place the sample: Hang the mask strap vertically on the test hook, and clamp the mask body between the lower clamps.

5. Test test:

Start the instrument, start the test, the test ends, the mask strap and the mask body are broken at the seam, and the test results are displayed on the screen.

Remove the tested sample, replace it with a new sample, and continue the test until all samples are tested. After the test is finished, press the statistics key to display the statistical results, including the average value, maximum value, minimum value, standard deviation, and coefficient of variation. After statistics, if you need to print a report, press print to automatically print the test report.